Volumetric Measurement of Bulk Material on a Moving Truck

Author: Release time:2023-08-23 08:00:17

Medium and large trucks are often used for material transportation, such as coal, ore, gravel, cement, etc. Since the cost settlement of bulk materials is generally based on material volume, it is particularly important for accurate volumetric measurement of the cargo being transported. In the past, manual estimation or volume calculation based on weight density was commonly used in bulk material transportation. This volumetric measurement method may cause a lot of errors and require a lot of manpower resources, resulting in low overall efficiency. Today we would like to introduce more details about Neuvition’s LiDAR Dynamic Truck Volumetric Measurement Solution.

LiDAR is a type of 3D sensor that has strong advantages in collecting three-dimensional information due to its physical characteristics. By using LiDAR for 3D modeling, the volume of the cargo loaded on the vehicle can be calculated. This solution can quickly and automatically output structured data according to needs in real-time, improving work efficiency and reducing significant losses caused by measurement errors. It truly achieves cost reduction and efficiency improvement through automation.

This system can scan and output data without a truck stopping, such as the length, width, and height of a truck. It can also generate a three-dimensional point cloud image of the truck and process cargo volumetric measurement based on the data. The system can output raw point cloud data and structured data according to user requirements. It uses communication protocols such as Ethernet/IP to exchange data with existing equipment systems and monitor their status. It can also provide integrated development and secondary development according to customer needs. This system has advantages such as real-time performance, high accuracy, a high level of automation, and broad applicability.

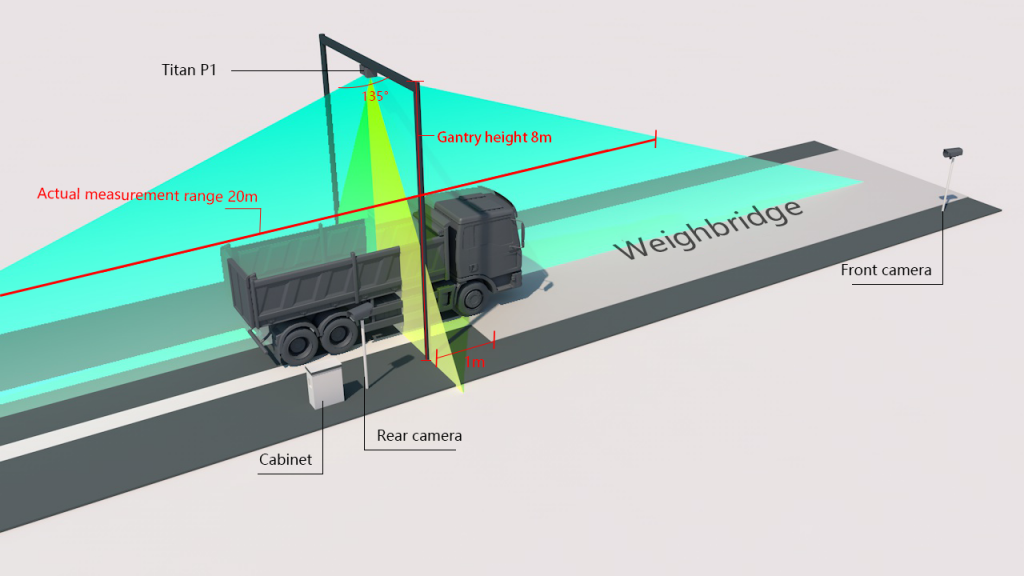

The hardware part consists of high-resolution LiDAR, cameras, edge computing devices, etc. The LiDAR is mainly used for speed measurement, scanning, and modeling, while the cameras are mainly used for license plate recognition. Depending on the installation environment and the length of vehicles being scanned, it is recommended to consider 1-2 sets of hardware devices to ensure complete coverage of the scanning area. If the data system already has license plate information or if license plate recognition has been achieved through other technologies, such as RFID cards, there is no need to install cameras.

Recommended Models: Single-line LiDAR Titan P1 and W1 series.

Installation Requirements

Ambient Temperature: -10°C to 50°C; ambient humidity: 10% to 80%. There should be a cover above the LiDAR to avoid direct sunlight.

The LiDAR is suspended on a gantry and scans vertically downward. The recommended height of the gantry is above 8m, and the effective coverage range of a LiDAR with a field of view angle of 135°at 8m can reach 20m. The specific height should be adjusted according to the site conditions and truck models.

The installation position should be flat to avoid volumetric measurement accuracy being affected by ground-level differences. It is recommended that trucks make a straight drive through the scanning area with a stable speed below 20km/h. Driving at low and constant speeds helps improve scanning effectiveness and measurement accuracy.

Application areas and product features

- Suitable for various types of conventional trucks (small trucks, large trucks, trailers);

- Suitable for volumetric measurement of bulk materials, such as sand, gravel, ore, and wood chips;

- Suitable for scenarios such as port terminals, warehouse loading and unloading, and construction site transportation;

- Real-time data output without the need to stop the truck, to improve transportation efficiency;

- Automated volumetric measurement and data processing to reduce errors caused by manual intervention;

- Convenient deployment and easy maintenance in the later stage;

- Not affected by external environmental interference and can work all day.

Software Functions

- LiDAR real-time scanning to obtain point cloud data of vehicles and objects being measured;

- Output truck length, width, height, and relative position of the baffle plate (if any);

- Identify truck license plate number, head, bucket, and tail fixed positions;

- Calculate the volume of the object being measured and estimate weight based on density;

- Data management includes historical data recording and querying functions;

- Provide SDK and API interfaces for easy integration development or customization based on customer requirements.