An Effective Method for Precise Positioning and Tracking of Loading and Unloading

Author: Neuvition, IncRelease time:2021-05-26 01:32:35

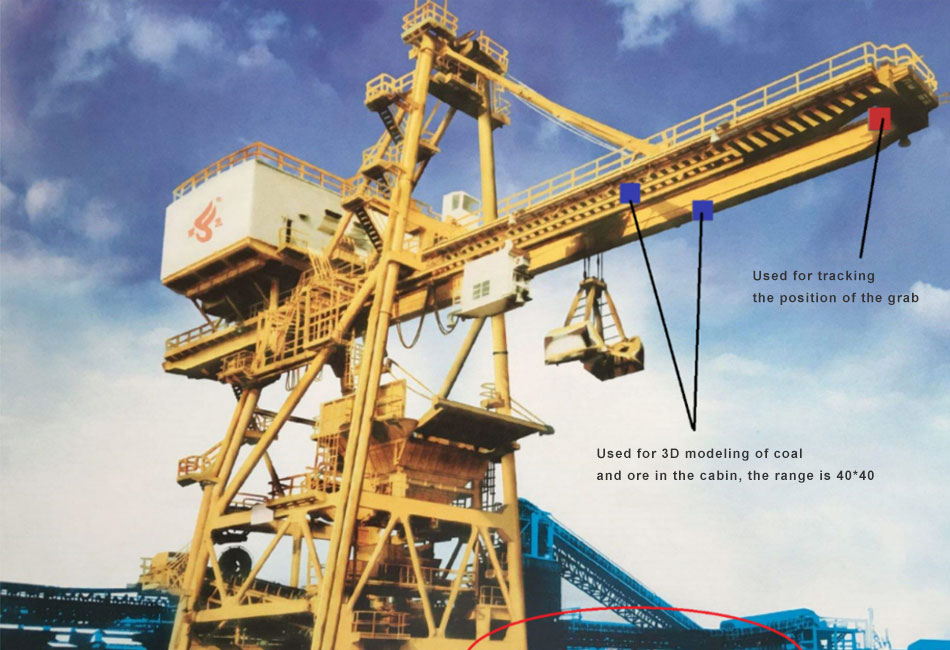

LiDAR is playing an increasingly important role in all kinds of industries. LiDAR-based precise positioning and tracking is an innovative solution for loading and unloading materials at power plants, docks, and ports.

![]()

With the rapid development of the waterway transportation industry, the scale and throughput of modern ports continue to increase, and the number of various loading and unloading equipment in the port is increasing. How to achieve efficient positioning and tracking of machinery is an important factor in improving the efficiency of loading and unloading at the terminal. The main bucket wheel stacker and reclaimer in port handling equipment is the core equipment for bulk cargo yard operations. It is a machine that combines stacking and reclaiming, a high-efficiency machine for digging and stacking loose materials such as coal, ore, and sand. It is not only suitable for power plants but also very suitable for docks and ports. Most docks and ports for transferring coal and loose materials use bucket-wheel stackers and reclaimers. The current positioning and tracking methods have some drawbacks.

To improve the efficient positioning and tracking of loading and unloading equipment, it is necessary to ensure that the stacker and reclaimer’s location stack recognition location, automatically determine the starting point of each layer of the stack, the end point and position tracking, end point memory, material flow to the center, cable protection, etc. Real-time positioning method, the central control room can monitor the operation process. Therefore, it is necessary to continuously track the position of the stacker and reclaimer, and to detect the three-dimensional position of the cantilever in real time to solve the problem of space collision prevention during stacking and reclaiming operations.

The positioning methods currently used by large machines on the market include human eye positioning, photoelectric encoder devices (optical code discs), mechanical laser ranging sensors, walking limit switches, and RFID methods. These methods of detecting position tracking have certain short-coming.

Challenge:

- Ability to measure the distance

- Short life

- High failure rate

- Low reliability

- The operation is complex

- There is out of control zone

Featured Product:

Neuvition 3D solid-state video LiDAR- Titan M1 is one of the highest resolution solid-state LiDAR sensors on the market. Using 1550nm eye-safe laser source, it can penetrate dense fog and dust and can work around the clock without the aid of a light source. It has the characteristics of high resolution, flexibility, and easy maintenance. Titan M1 solid-state LiDAR has a resolution of 480 vertical lines, a maximum of 1750 pixels per scan line (resolution of 1750 x 480), a maximum data rate of 1.5 million points per second, multiple returns, and an effective detection range of 200 meters. Real-time output of 3D point cloud data, or fusion of 3D point cloud data with camera data, and transfer back to the central control platform to achieve highly precise positioning and tracking.

Solution:

The LiDAR is installed on the lower plane of the girder, and two devices are installed to face different scanning coverage areas, and the upper boundary of the scanning is adjusted according to the horizontal field of view and the vertical market angle. The 3D solid-state LiDAR sensor performs real-time scanning and 3D point cloud data collection and return. Neuvition’s software platform separates the grab from the overall point cloud, outputs the grab point cloud separately, and provides coordinate information in real-time.

Fields of applications:

- Power Plants

- Docks

- ports

Key Benefits:

- Ability to measure the distance

- Ability to measure the size

- Work well in a low lighting situation

- Depth measurement

- High precision

- Precision less affected by distance

Contact us:

Neuvition can provide customers, according to their requirements, with efficient tracking and positioning solutions to loading and unloading equipment based on the solid-state LiDARs of our Titan series. If you have any questions, please feel free to contact us. We are always glad to share the solutions. Fill in the form below or send your request to contact@neuvition.com.